The overall aim of the project is to bring about behavioural and technological changes in SMEs in the manufacturing and logistics sectors, generating positive outcomes for the regional economies and environment, in line with the principles of sustainable development.

The project promotes SMEs’ communication with business associations and R&D&I organizations regarding their needs and issues in the field of energy efficiency and transport and logistics optimization. This flow of information facilitates the detection of opportunities and encourages the development of solutions adapted to their needs. The core of the project is innovation in and for SMEs, including knowledge management and customization of available technologies.

As part of the CO-EFFICIENT project, two living labs were set up in each of the five participating countries: Slovenia, Italy, France, Croatia and Spain. Within these 10 living labs, specific pilot projects were carried out, the common objective of which was to improve the energy efficiency of participating SMEs. In addition, the results of the pilot projects provided enough information to assess the validity of the chosen framework as an innovation development environment. Specifically, each of the living labs included between three and five SMEs (end-users), a research centre, and a business association that would channel the transmission of information to the rest of the living labmembers.

The first living lab was focused on the use of different tools to optimize transport and logistics in SMEs. The suitability of specific tools among those available depended on the SMEs that formed part of the living lab. In particular, in the cases headed up by Fundación Valenciaport, the following tools were evaluated:

- Planning assistant in container transport companies

- Document scanning software

- Recording and minimizing CO2 emissions in companies with their own fleet.

The second living lab was focused on energy management in SMEs and was aimed at developing support tools to help ensure their productive processes were as energy efficient as possible.

Lastly, the project involved the development and testing of a methodology to allow SMEs’ energy certification. Although this task did not directly form part of either of these living labs, it relates to both and provided added value to the project in terms of promoting and stimulating energy efficiency in the industry.

The project consortium consisted of 10 partners from 5 countries in the Mediterranean region. In addition to Fundación Valenciaport, the following entities participated: CIERVAL (Spain), University of Maribor (Slovenia), Mura Regional Development Agency (Slovenia), Institute of Transport and Logistics (Italy), Association of the National Confederation of Artisans and SMEs of the province of Modena (Italy), SATA Advanced Technology Applications (Italy), Regional Delegation of the AFT in Rhône-Alpes (France), Regional Development Agency of Eslavonia and Baranja (Croatia), Osijek Centre for Entrepreneurship (Croatia)

Regarding the objectives of the pilot projects carried out in the living labs, the following results were achieved in the actions carried out in Valencia.

- Planning assistant in container transport companies

The bulk of the container traffic between the port and importers/exporters is by truck. The companies that perform this work often receive transport orders with little advance warning in terms of when the truck has to be at the client’s premises, which makes daily planning difficult. As a result, the assignment of drivers and trucks to transport orders may be less than optimal. The use of assistants to improve this process will thus impact the costs and the energy consumption (mainly fuel) of these companies.

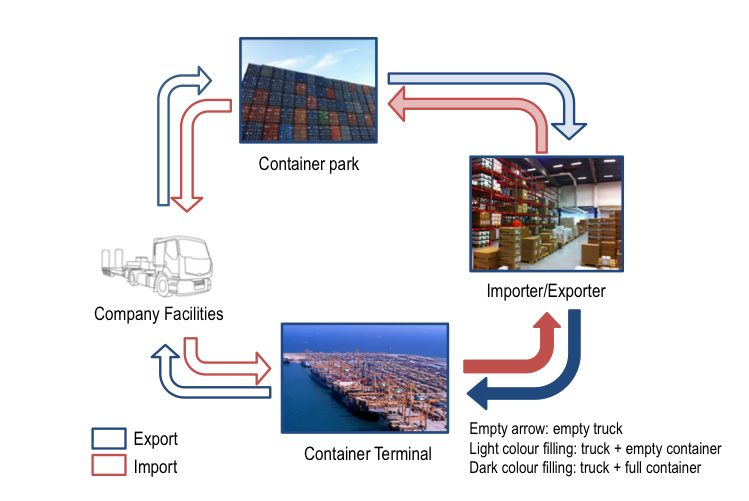

The aim of this pilot was to develop a planning assistant that proposes the best assignment at any given moment. To that end, it takes into account the specific characteristics of container transport; in particular, accounting for the fact that each of the import or export transportation operations involves a series of movements between three sites (container depot, the client’s premises and a container terminal).

The development of the tool made use of real data on previous transport assignments by the container transport companies participating in the pilot. This enabled the detection of optimal assignment criteria (of great value in an environment as dynamic as assignment planning), which was fundamental to the development and tuning of the assistant. Logistics company SYRGROUP participated in this pilot.

Scanning of transport documents.

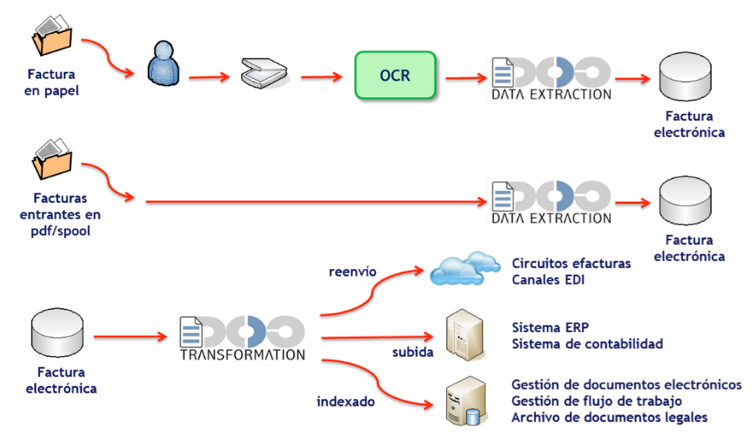

As part of transport companies’ day-to-day work, a huge volume of documents have to be handled and the content has to be entered into their business management systems. At present, a great deal of this management is carried out manually, a costly and error-prone process. The use of tools for converting documents into electronic format allows SMEs to migrate towards paperless management, which is more efficient, requires fewer resources and is more environmentally friendly.

Within the living lab dedicated to the Optimization of Transport and Logistics, a pilot was carried out that made use of a document scanning tool developed in an earlier European project (eBest), in which some of the CO-EFFICIENT project partners were involved. The tool identifies the values (text and numeric) contained in the document to be scanned and classifies them according to previously established criteria. The result of this reading is stored in a structured output file that can be used by a wide variety of systems. For example, the program reads an invoice in pdf format, identifies the fields (invoice number, client name, tax number, line items, etc.) and stores them in an xml file. Said file can be read by the company’s management system in order to store the fields in the company database. The invoice can thus be entirely managed without requiring any manual processes.

El objeto del piloto llevado a cabo en el proyecto CO-EFFICIENT es la gestión sin papeles de las órdenes de transporte. La empresa participante en este piloto fue Transportes Ballester.

Registro y minimización del CO2 emitido en empresas con flota propia

El tercero de los pilotos incluidos en el living lab Optimización del Transporte y la Logística pretende incentivar a las empresas de transporte para la adopción de acciones que consigan reducir su consumo de combustible. En este sentido se han aprovechado dos iniciativas promovidas respectivamente por el gobierno español y francés: el registro de huella de carbono y el programa Objectif CO2. El piloto aprovecha los aspectos comunes y complementarios de ambas iniciativas resultando finalmente en una metodología estructurada que permite a las empresas con flota propia calcular la cantidad de CO2 emitida y establecer un plan de reducción con acciones específicas que se debe llevar a cabo durante los tres años siguiente a la adhesión al plan. Además de los beneficios directos derivados de la implantación del plan de reducción, en el piloto se ha asistido a las empresas en la inscripción en el registro de huella de carbono, desarrollado por el ministerio de medio ambiente español, y la obtención del sello correspondiente.

As a result of the pilot, four transport companies obtained the carbon footprint register seal: SYRTRANS, Ballester, Transtorres and ESK.

Energy efficiency self-diagnostic tool.

The main objective of the pilot carried out in the living lab created for energy efficiency innovation was to develop a self-diagnostic and improvement tool that allows SMEs to detect aspects of their production process and facilities that can be improved in order to achieve a more efficient use of the energy consumed. The tool has drawn on the valuable information provided by a series of energy audits carried out at the premises of the SMEs participating in the living lab. In particular, three energy audits were carried out in the Spanish case, in SMEs of different sizes and types: a textile company (Mora), a manufacturer of plastic packaging (ESB) and a logistics operator specializing in container transport (SYRGROUP). The development of this pilot directly provided participating companies with an added value, since the results of the energy audits have enabled SMEs to measure and characterize their energy consumption, and correct inefficiencies in their energy use and management.