The fact that Industry 4.0 is generating a digital revolution in the freight transport sector is beyond doubt. The digitization of transport is aimed at achieving more efficient, predictive operations and services through automation.

Motivated by the major economic and social impact expected of the freight transport industry, this project seeks to improve the effectiveness of the short- and medium-term operations planning of a global leader in container transport. With the help of artificial intelligence, the integration of different data sources and the use of innovative user-friendly visualization tools, an improvement in the quality and level of service to clients is expected. The quality of the forecasts will help prevent a lack of availability of containers in certain situations, thus allowing demand to be met.

The new system will be able to predict the available stock of empty containers, which will directly improve quality of life by minimizing unplanned repositioning movements of equipment. The elimination of these movements will be directly beneficial to the environment, as it will cut out the set of externalities associated with the transport of these containers: gas emissions, noise, congestion, etc. On the other hand, the system will independently manage prediction models so that it can quickly adapt to changing patterns in supply, demand and container traffic. This will reduce the resources needed for the technical maintenance of the tool.

The management of the empty container fleet (empty equipment) carried out by local agencies of large shipping companies is a complex activity to optimize for a number of different reasons, notably the level of operational uncertainty involved in the receipt and delivery of containers, which makes forecasting difficult. The lack of support tools capable of making reliable forecasts of these operations gives rise to poor management of the equipment and in repeated problems that result in extra costs and dissatisfied clients (freight forwarders, logistics operators, exporters and importers). Such problems include the repeated lack of equipment needed for export operations at certain locations and times, and the unplanned repositioning of equipment due to bad decisions.

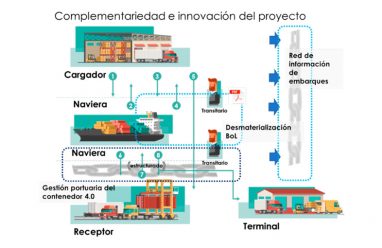

The aim of the project is to develop and pilot test an innovative system for the management of empty equipment (hereinafter e2rm – empty equipment repository management) that applies machine learning algorithms to produce reliable predictions of operations involving the receipt and delivery of containers. A further objective of the project is for the e2rm system to be able to easily integrate with shipping agents’ other systems and operations, and also for it to have a control panel and alarm system aimed at anticipating problems and optimizing decisions regarding the repositioning of equipment.

The main technical problem to be solved stems from the complexity of the scenario due to the volume and diversity of data that must be processed for the predictions, as well as the difficulty of programming rules that depend on multiple factors and may overlap. These elements of the problem pose a challenge which can be addressed by turning to the field of artificial intelligence, with the use of automatic learning algorithms and techniques such as neural network modelling. The development of a quick, responsive solution that delivers good predictions is the first technical challenge to overcome.

Another of the technical problems or challenges is the development of e2rm as a user-friendly tool to assist decision-making based on this automatic learning solution for forecasting. Moreover, e2rm should be able to integrate with the rest of the organization’s systems, as well as with the processes and day-to-day operations of the equipment control, transport and commercial departments of a container liner shipping agent. The variety of internal systems (of the shipping agents) and external systems (port and inland terminals, container depots, etc.) that process information relevant to forecasting make the integration of the new e2rm into said systems a new technical challenge; solving this challenge will require the development of middleware capable of communicating with multiple data sources and of moving information in an orderly and standardized way to the new e2rm system.